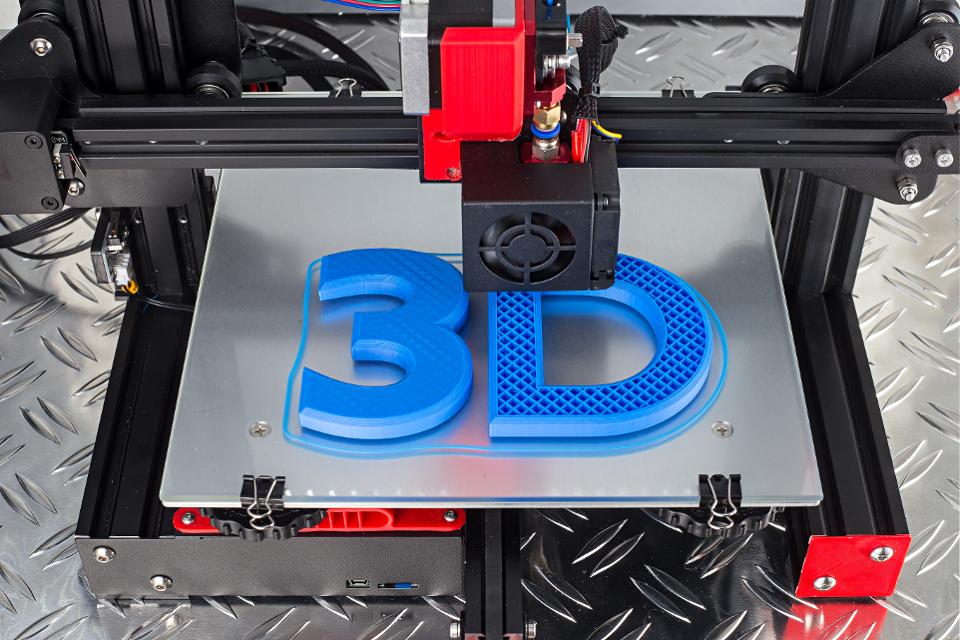

Researchers at the University of Minnesota Twin Cities have developed a groundbreaking 3D printing method that creates human tissue structures with lifelike qualities, offering new possibilities for surgical training and medical education. Their work, recently published in Science Advances, demonstrates how advanced printing techniques can produce tissues that replicate the stretch, strength, and directional flexibility of natural organs, in contrast to older models that were stiff and simplistic. By controlling the internal micro-patterns of the printed material, the team was able to tailor the mechanical properties of the tissues and even predict their behavior using a mathematical model. To enhance realism, they incorporated a process that embeds microcapsules filled with blood-like fluids directly into the tissues during printing, ensuring the liquid remains intact without interfering with the structure. This innovative step allows the models to better mimic the handling characteristics of real human tissue. Lead author Adarsh Somayaji, a recent Ph.D. graduate in mechanical engineering, explained that the approach could significantly improve the quality of surgical training, ultimately leading to better patient outcomes. In a pilot evaluation, surgeons reported that these 3D-printed tissues provided superior tactile feedback and responded more realistically to cutting compared to conventional models. While further work is needed to scale up production and adapt the method for a wider range of applications, the researchers envision its use in creating anatomically diverse training models, developing prototype bionic organs, and integrating materials that respond to surgical tools such as electrocautery. The project was a collaborative effort involving Somayaji, Matthew Lawler from biomedical engineering, and Zachary Fuenning and Michael McAlpine from mechanical engineering at the University of Minnesota, in partnership with the CREST Lab and Wang Lab at the University of Washington. This breakthrough highlights the growing role of 3D printing in shaping the future of medical simulation and personalized healthcare solutions.